This collaborative project was the first of it's kind within the adidas group. It began in Portland, OR, USA. For 3 months, a team of 4 interns gathered together at least once a week and aimed to spark a fresh perspective on designing the next generation of footwear and apparel products for a completely new consumer. Working together as a dedicated collective, we synergised the expertise from our respective departments - originals, innovation, training, and basketball. Below, you'll see a glimpse of our design journey, which includes extensive consumer research, trend forecasting, ideation, and experimentation. Our project was shared with global design executives and became highly influential in the development of the commercial release of the nmd

Originals - Ivan Jaddou

Innovation - Kristina Marrero

Training - Thea Mashofsky

Basketball - Erick Ikeda

Mentors - John Acevedo, Liz Callow, Erik Hernandez, Josh Herr, Brian Foresta, Peter Moore

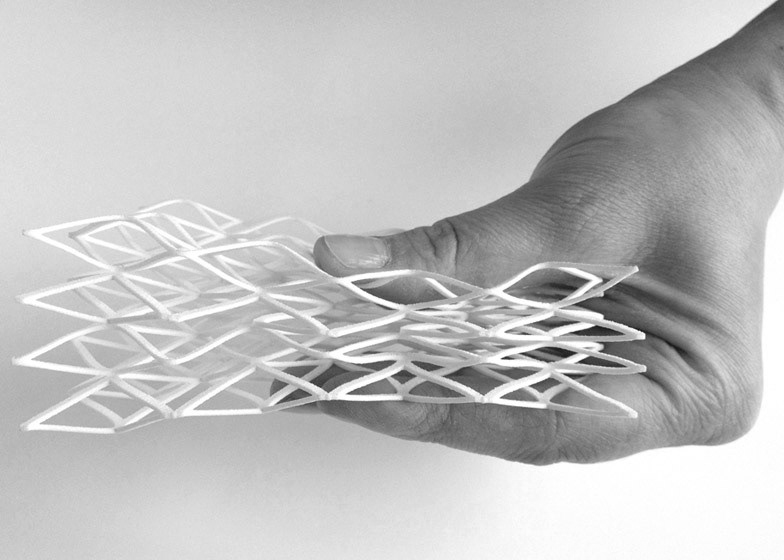

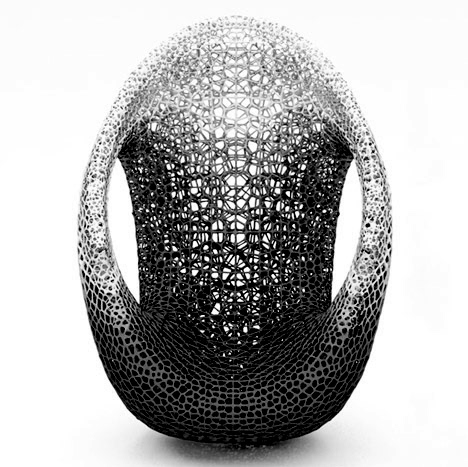

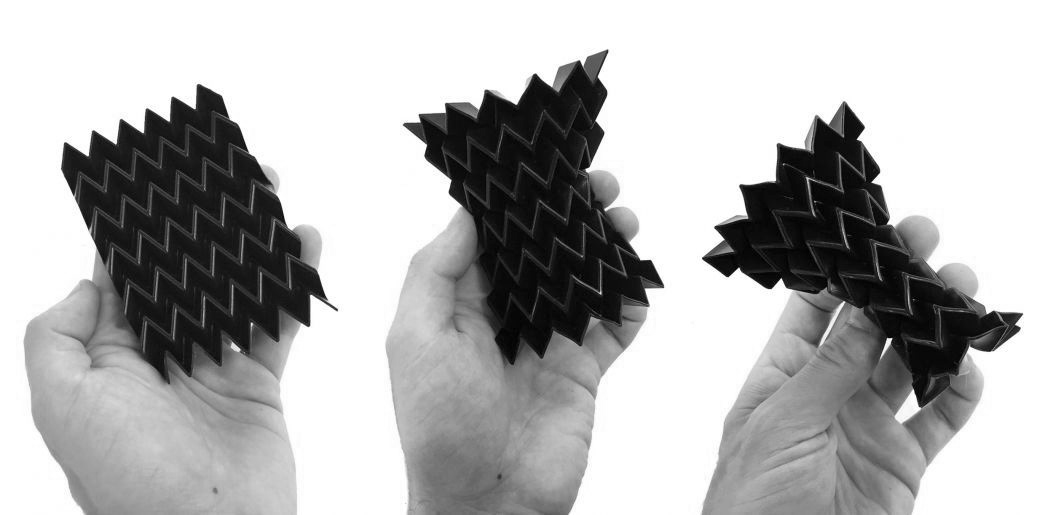

AESTHETICALLY AND FUNCTIONALLY, WE WERE INSPIRED BY ORIGAMI AND COLLAPSIBLE STRUCTURES FROM DESIGNERS AT THE CUTTING EDGE OF THEIR FIELDS, FROM ISSEY MIYAKE IN FASHION TO ZAHA HADID IN ARCHITECTURE. THESE INNOVATIVE APPROACHES TO MATERIALS AND TECHNIQUES HAVE THE ABILITY TO ADAPT TO DIFFERENT SHAPES, SIZES, CONSIDERING THE LIFE OF THE PRODUCT IN A UNIQUE AND THOUGHTFUL WAY.

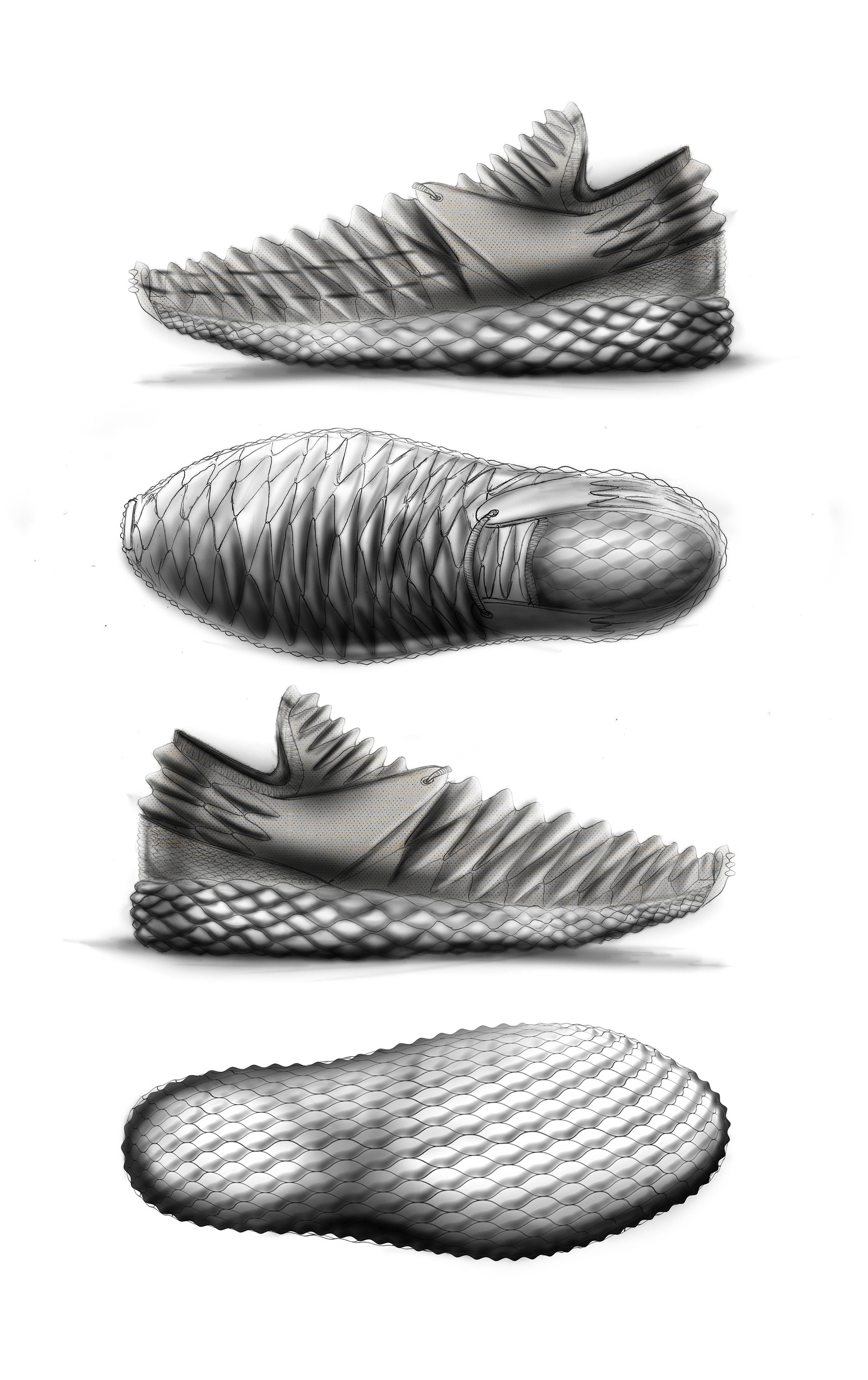

SOME OF OUR SKETCHES APPLIED A BOOST SOLE UNIT FOR MAXIMUM ENERGY RETURN, WHILE ANOTHER IMPLIED AN EXPANDABLE AND COLLAPSIBLE SOLE STRUCTURE.

THIS SKETCH APPLIES THE ADIDAS 4D FUTURECRAFT SOLE UNIT.

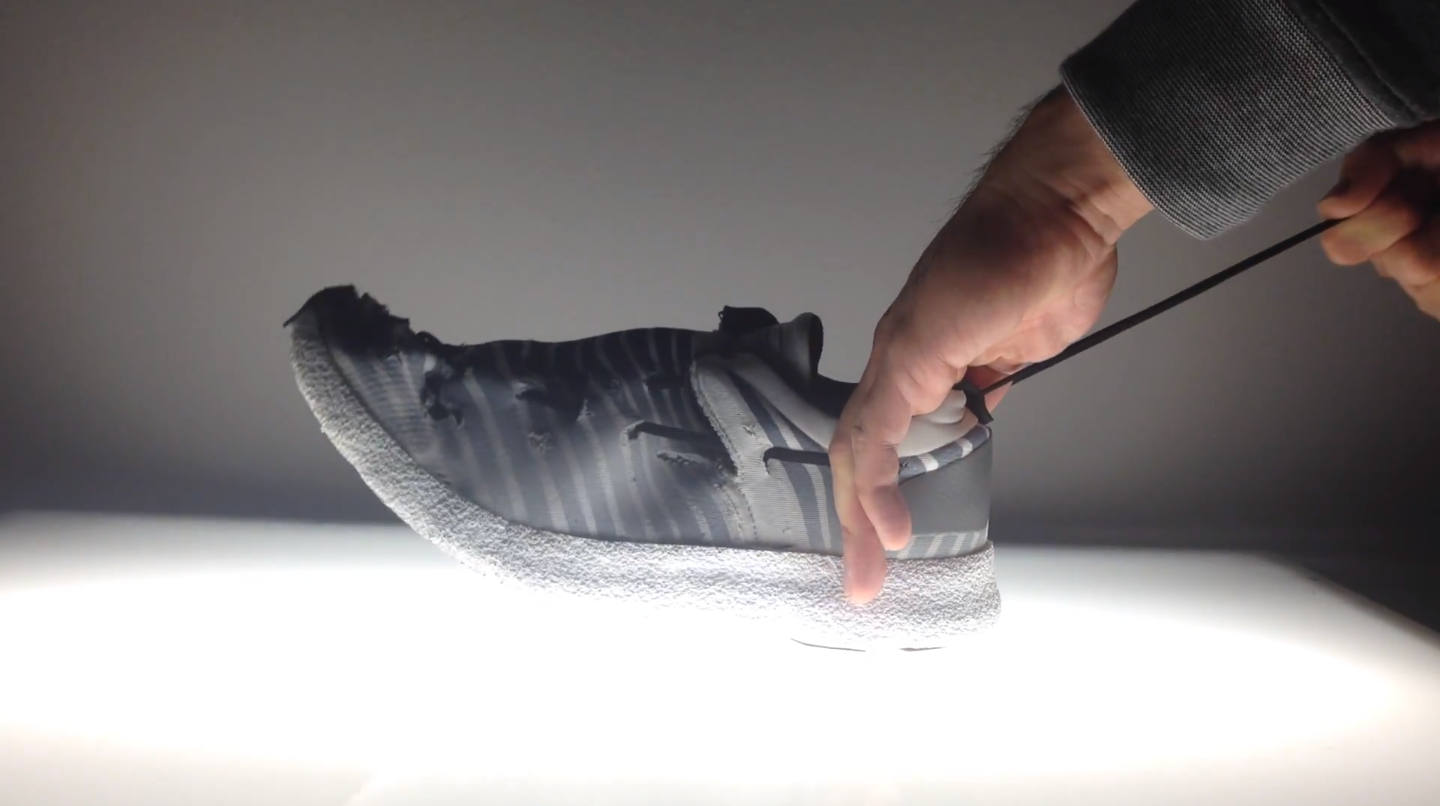

EXPERIMENTS USING PLEATING AND LACES TO CREATE COLLAPSIBLE STRUCTURED MATERIAL THAT CAN ADAPT TO DIFFERENT ACTION POINTS BETWEEN LIFESTYLE AND PERFORMANCE.

THROUGH ITERATIVE MOCKUP MAKING, WE FIGURED OUT HOW TO TRANSFORM THE SHAPE OF THE SHOE USING AN INNOVATIVE CINCHING LACE SYSTEM THAT RAISES THE TOESPRING AND HEELSPRING. IT CHANGES THE SHAPE AND FIT OF THE SHOE FROM A MORE LOOSE AND FLAT SILHOUETTE, WHICH ACCOMMODATES MORE LIFESTYLE AND RELAXED PURPOSES, TO A TIGHT, PERFORMANCE-DRIVEN ROCKING MOTION FIT THAT ACCOMMODATES A ROLLING FOOTSTRIKE FOR MORE RUNNING AND ATHLETIC PURPOSES. AFTER MUCH TRIAL AND ERROR, WE LEARNED THAT THE LACING SYSTEM NEEDED TO BE DESIGNED SO THAT THE TOESPRING WOULD BE RAISED STARTING WITH THE BIG TOE (WHICH HOLDS THE MOST WEIGHT AND PRESSURE) AND THE FOLLOWING TOES THEREAFTER.

OUR MOCKUP/TAPEUP IDENTIFIES THE PLEATED AREAS WITH BLACK LINES. OUR LACING SYSTEM CONSIDERS INNOVATION IN BOTH FUNCTIONALITY AND AESTHETICS. THIS LACING TECHNIQUE PROVIDES AN VISUAL THAT HASN'T BEEN SEEN BEFORE.

OUR INTERNAL MILAGE TRACKER USING AN ACCELEROMETER ALLOWS THE USER TO UNDERSTAND HOW FAR THEY HAVE BEEN WITH THEIR SHOES AND ENCOURAGES THE DEVELOPMENT OF AN EMOTIONAL ATTACHMENT TO THE PRODUCT. WE CONSIDERED A SHOE AS A FORM OF TRANSPORTATION, ANALOGOUS TO CARS OR OTHER VEHICLES WHERE THE USERS COMMONLY DEVELOP FONDNESS AND MEMORIES WITH THEM AND BASED ON THE MILEAGE OF THE PRODUCT. THIS SIMPLE CONCEPT UNLOCKED MANY IDEAS AND QUESTIONS FOR US.

COULD WE USE THIS MILEAGE TRACKER TO GAMIFY THE EXPERIENCE OUR USER HAS WITH THE SHOE? PERHAPS UNLOCKING ACHIEVEMENTS OR COMPANY DISCOUNTS AT 1K 5K 10K MILES? COULD WE BUILD A DIGITAL ECOSYSTEM AROUND THE IDEA OF MILEAGE TRACKING AND COMPETITIVE LONGEVITY? HOW COULD THIS IDEA AFFECT THE CUSTOMER'S BRAND LOYALTY? HOW COULD THE MARKET OF BUYING AND SELLING USED SHOES WITH MILEAGE INFORMATION CHANGE OUR IDEAS OF THE PRODUCT LIFECYCLE? COULD THIS TECHNOLOGY HELP US BETTER UNDERSTAND PRODUCT LONGEVITY AND SUSTAINABILITY?

OUR COLOR PALETTE WAS INFLUENCED BY THE GREAT OUTDOORS AS WELL AS SOME OF ADIDAS EQUIPMENT PRODUCT HERITAGE.

OUR PROJECT WAS PRESENTED TO THE GLOBAL TREND TEAM AND GLOBAL DESIGN EXECUTIVES. IT BECAME THE INSPIRATION FOR THE CREATION AND DEVELOPMENT OF THE NOW HIGHLY SUCCESSFUL ADIDAS NMD FRANCHISE.